Professor James Economy's Group

|

|

[Activated Carbon Fibers] [Ion Exchange Fibers] [Chelating Fibers] [Membranes] [Porous Inorganic Fibers]

Advanced

Membranes for Desalination and Wastewater Treatment The objective

of this project is to develop low fouling, cost

effective, durable reverse osmosis (RO) and

nanofiltration (NF) membranes for desalination and

wastewater treatment which greatly outperform current

state-of-the-art RO and NF membranes. We are currently

preparing and screening a series of new membrane

materials including aromatic liquid crystalline,

non-liquid crystalline thermosetting polyesters,

hyperbranched poly(imide-ester)s and

poly(imide-silsesquioxane)s, hyperbranched

aromatic poly(amide-silsesquioxane)s and

poly(amide-urea)s, cross-linked functional

poly(etheretherketone)s, selected high temperature

polymers including polyquinoline, polyquinoxaline,

polybenzthiazole, polybenzoxazole, polybenzimidazole, and

ladder polymers based on some of these structures, etc.

These membrane materials will be used to develop dense

and thin-film composite (TFC) membranes. At the same time

we will determine the efficiency of such membranes for

desalination and wastewater treatment. The most promising

systems will be modified further to control the membrane

properties. A variation on the above theme will involve

taking advantage of work currently underway in the

microelectronics industry to prepare dielectric films

with closed micropores to determine any possible

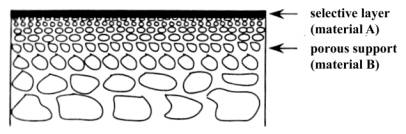

advantages to that kind of morphology. Thin-film composite

membranes as shown above for desalination will be

developed by spin-coating or dip-coating the

as-synthesized materials (material A) on the surface of

the porous support (material B) such as polysulfone or

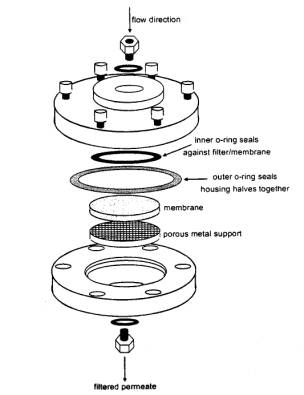

ceramic membrane. Evaluation of the prepared

membranes for desalination will be carried out using the

above filtration cell housing. The membrane will be

placed on a support screen and sealed in filter holder

using an O-ring assembly. This filtration cell will be

used for initial proof-of-concept demonstrations and will

be incorporated into an in-house built system. Activated

Microporous Membranes These

membranes will have continuous pore structures on the

order of 10 angstroms with carefully controlled pore

chemistry (acidic vs. basic character) analogous to

activated carbon materials currently produced by this

group. When pore size and surface chemistry is

optimized this should allow polar water molecules to pass

but not ionic molecules. It is believed that this

technology will compete with reveres osmosis (RO)

membranes for desalination and microporous membranes for

other water purification applications such as organics

removal. These activated membranes should have numerous

advantages over RO such as lowered pressure drop,

increased flow rate, greater strength and fouling

resistance. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||