Professor James Economy's Group

|

|

[Carbon/BN Composite] [AlB2 Composite] [Polymer Composites]

Aluminum

/ Aluminum Diboride Metal Matrix Composites In-situ

aluminum matrix composites based on the

aluminum-copper-boron ternary system have been developed

for the first time. Aluminum diboride, one of many stable

crystalline phases naturally present in the alloy system,

is exploited as a reinforcement. AlB2 exists

in the aluminum matrix as single crystal high aspect

ratio flakes. Proper heat treatment allows for the

preparation of an aluminum composite containing only this

phase. Reinforcement volume fraction can be varied from 0

to 20% by control of alloy composition and by the use of

a modified squeeze casting apparatus. At 20v/o loading of

AlB2 an 80% increase in strength over the

matrix alloy is observed. Wear and creep resistance of

these composites is also found to be excellent. Current

research is focusing on the following areas: Redtermination

of the Al-B phase diagram. Considerable

disagreement exists in the literature concering the Al(L)

+ AlB2 -> Al(L) + AlB12

peritectic transition temperature. Experiments to

determine this temperature are underway. Preparation

of AlB2 MMC's for comodity

materials. Using

comodity boron sources we project that 20 % AlB2

MMC's can be prepared for less than $5/Kg. Preparation

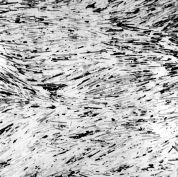

of macroscopic oriented boride structure in aluminum. Macroscopic

structures of oriented borides have been created in

aluminum. It is believed that these structures could lead

to composites with unique properties. Selected

Micrographs Related

Publications The

following is a list of related publications which you may

find of interest. 1.

Deppisch, G. Liu, J.K. Shang, and J. Economy; Fabrication

of AlB2 Flake Reinforced Al-Alloy Composites 2.

C. Deppisch, G. Liu, J.K. Shang, and J. Economy; Effect

of Cooling Rate on the Crystallization of AlB2 Flakes in

Al Composites 3.

L. Wohrer, A. Wosilait, and J. Economy; SAMPE 18,

340-68 (1973). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||